Process Automation

Optimize. Automate. Outperform. Unlock Efficiency in Every Process.

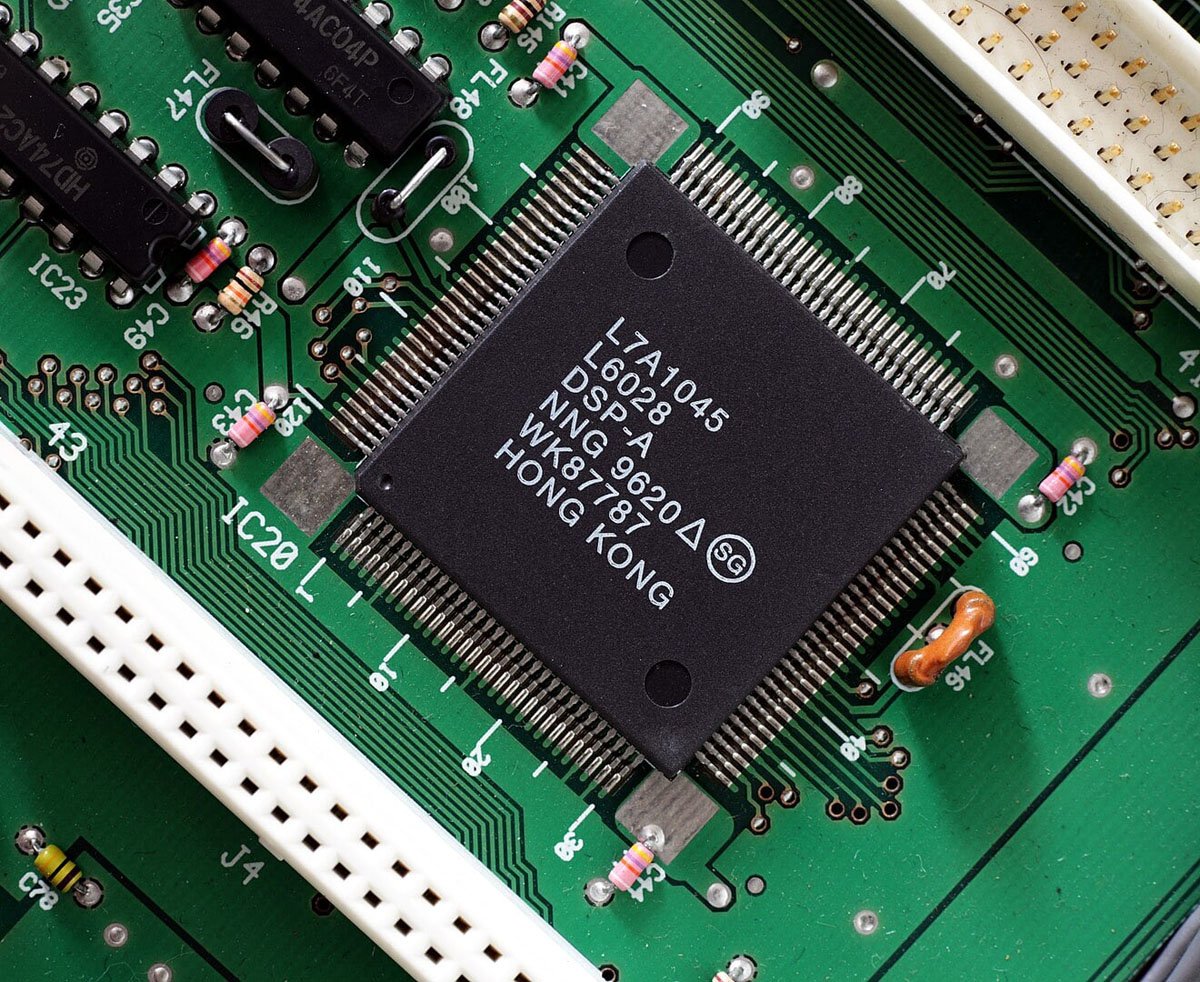

We provide industrial clients with expert consulting, design, and implementation services focused on process automation. Our mission is to transform your operations, increase throughput, and reduce operating costs by integrating reliable, intelligent control systems with robust mechanical design.

We don’t just automate; we engineer a smarter way to manufacture.

Our Process Automation Services

Our services cover the full spectrum of automation projects, from initial system audit and feasibility studies to commissioning and long-term support.

1. Automation Strategy & Assessment

We begin with a data-driven evaluation of your current operations to identify the highest-impact opportunities for automation.

- Process Audits: Detailed analysis of existing manual or legacy processes to pinpoint bottlenecks, waste points, and safety risks.

- Feasibility Studies & ROI Analysis: Determining the technological and financial viability of proposed automation projects and calculating clear Return on Investment (ROI).

- Technology Roadmapping: Developing a phased plan for migrating to modern control systems (PLC, DCS, SCADA) and integrating Industrial IoT (IIoT) capabilities.

2. Design & Engineering for Automation

Our combined expertise in design and controls ensures your automated solutions are safe, scalable, and built to last.

- Control System Design: Designing and programming the PLC/PAC logic, HMI screens, and DCS systems that govern your operations (Expertise across Allen-Bradley, Siemens, Rockwell, etc.).

- P&ID and Electrical Schematics: Creating detailed Piping and Instrumentation Diagrams and panel schematics compliant with industry standards (e.g., NFPA, IEC).

- Machine Safety Integration: Designing and implementing safety-rated control systems (GuardLogix, Safety PLCs) to meet local and international safety regulations.

3. Robotics & Advanced Controls Implementation

We integrate cutting-edge hardware and software to create high-speed, flexible production lines.

- Robotics Integration: Deployment of collaborative and industrial robots for tasks like pick-and-place, welding, assembly, and quality inspection.

- Vision Systems: Integrating advanced Machine Vision for precision guidance, quality control, sorting, and measurement.

- SCADA and MES Solutions: Implementation of Supervisory Control and Data Acquisition (SCADA) and Manufacturing Execution Systems (MES) to provide real-time data visibility, reporting, batch tracking, and full enterprise-level process control.

The BaaS Systems Automation Advantage

Focus Area | Benefit to Your Business |

Increased Throughput | Faster cycle times, reduced downtime, and higher overall equipment effectiveness (OEE). |

Data-Driven Quality | Automated inspection and real-time process monitoring virtually eliminate human error and ensure consistent, verifiable product quality. |

Cost Reduction | Lower operational labor costs, reduced energy consumption, and minimized material waste through optimized processes. |

Future-Ready Systems | We design using modular, open architectures that are scalable and integrate seamlessly with new Industry 4.0 and IIoT technologies. |