Product Design Services

Design Smart. Build Better. Automate Success.

We are not just product designers—we are Engineers of Manufacturability. We specialize in designing industrial products, equipment, and complex components with automation in mind, ensuring your innovative concepts can be efficiently and reliably manufactured at scale.

Our expertise merges creative design with deep knowledge of robotics, control systems, and assembly processes, giving you a tangible competitive edge.

Our Integrated Product Design Services

From initial concept to final production-ready files, we manage the entire product development lifecycle, focusing on efficiency, cost control, and performance.

1. Concept & Feasibility

We start by grounding your vision in technical reality.

- Ideation & Conceptualization: Rapid prototyping and brainstorming to define the product’s core functions and user experience.

- Design-for-Automation (DfA) Analysis: Early-stage consulting to ensure the product’s components and assembly sequence are optimized for robotic or automated manufacturing lines.

- Proof-of-Concept Prototyping: Creation of functional prototypes to validate key features and user acceptance before investing in full-scale tooling.

2. Mechanical & Electrical Engineering

We deliver comprehensive, robust engineering packages ready for mass production.

- Detailed 3D Modeling: High-precision CAD modeling (e.g., SolidWorks, Creo) for all components and assemblies.

- Design-for-Manufacturing (DfM): Optimizing part geometry, material selection, and tolerances to minimize tooling complexity and production cost.

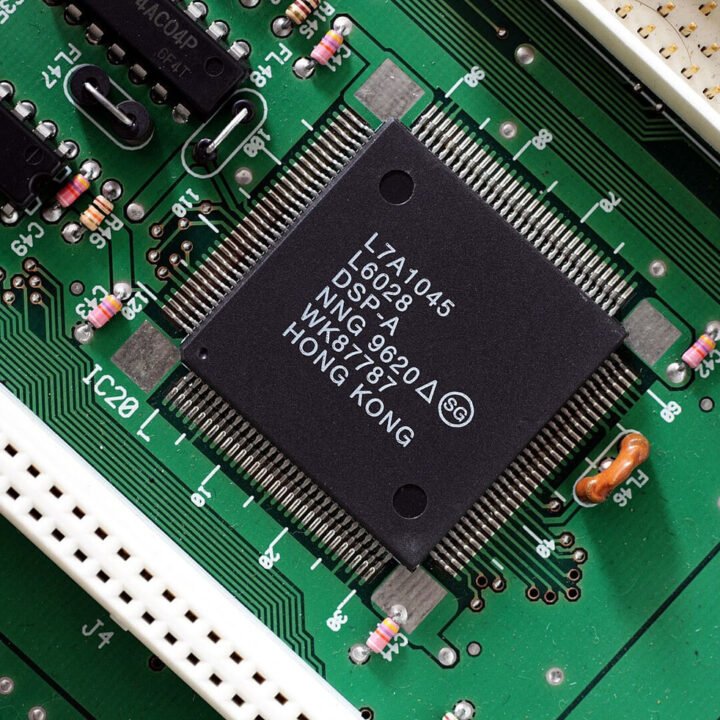

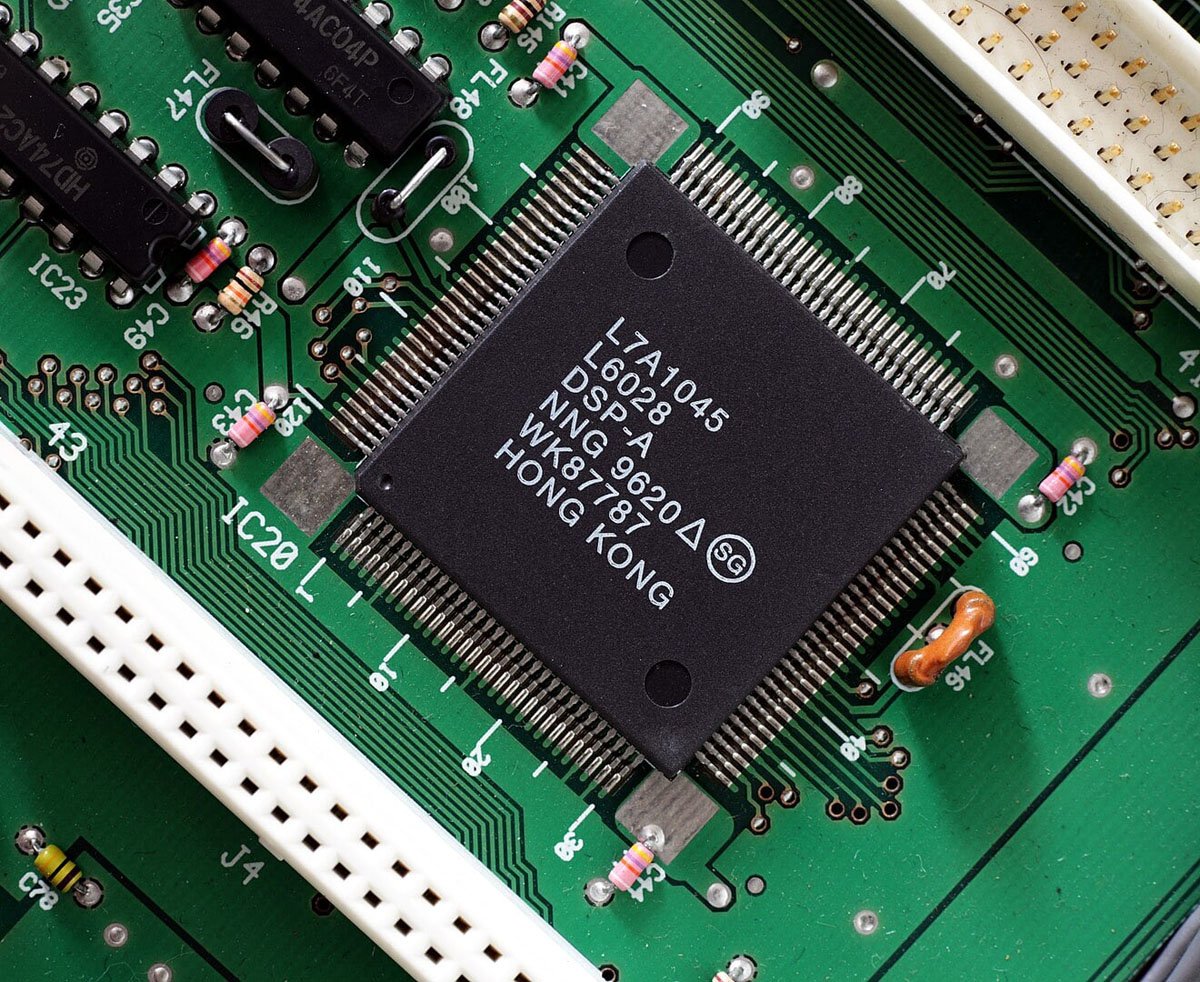

- Custom Electronics & Enclosure Design: Designing custom PCBs, selecting appropriate sensors and actuators, and creating robust enclosures suitable for industrial environments.

- Stress & Fluid Analysis (FEA/CFD): Validating the performance, durability, and safety of your product under real-world operating conditions.

3. Automation Integration & Production Planning

This is where our unique expertise in automation maximizes your product’s profitability.

- Manufacturing Process Design: Defining the most efficient, automated flow for assembly, inspection, and packaging.

- Tooling & Fixture Design: Designing all necessary production aids to work seamlessly with your chosen automation equipment (e.g., end-of-arm tooling for robots).

- Control System Architecture: Specifying the logic controllers (PLCs), drives, and communication protocols your product’s test and assembly lines will use.

- Supplier & Vendor Management: Consulting on sourcing, quoting, and managing the tooling and equipment vendors necessary for launch.

Why Choose BaaS Systems?

Focus Area | Our Advantage | Result for You |

Automation-First | We design components and assemblies to be picked, placed, and tested by machines, not just by people. | Lower Unit Costs and Higher Production Yields from Day One. |

Risk Reduction | We identify and solve manufacturing risks in the design phase, preventing expensive, time-consuming issues on the factory floor. | Faster Time-to-Market and Reduced Capital Investment in re-tooling. |

Holistic Expertise | Our team blends industrial design, mechanical engineering, and control system programming. | One Point of Contact and a single, unified solution from concept to production launch. |