Software Defined Engineering

Code the Future. Define the Vehicle. Master the Industrial IoT.

The future of industry is digital. We empower manufacturers to transition from hardware-centric design to Software-Defined Engineering (SDE), ensuring your products—from complex industrial machines to next-generation vehicles—are flexible, upgradeable, and revenue-generating.

We specialize in designing systems where function is dictated by code, providing the agility required for today’s rapidly evolving market.

Our Core Service: Software-Defined Vehicle (SDV)

The vehicle is the ultimate software-defined machine. We are your end-to-end partner for building and managing the SDV architecture.

1. SDV Architecture & Design

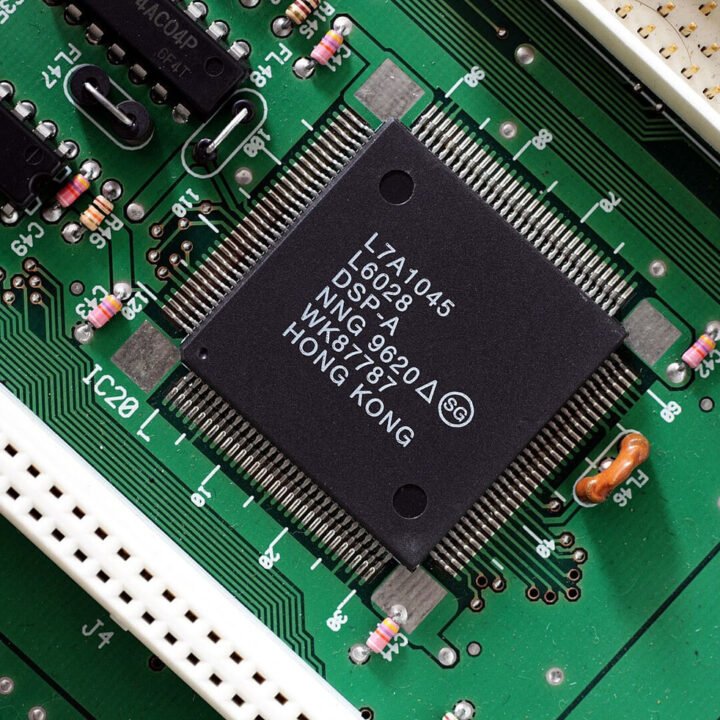

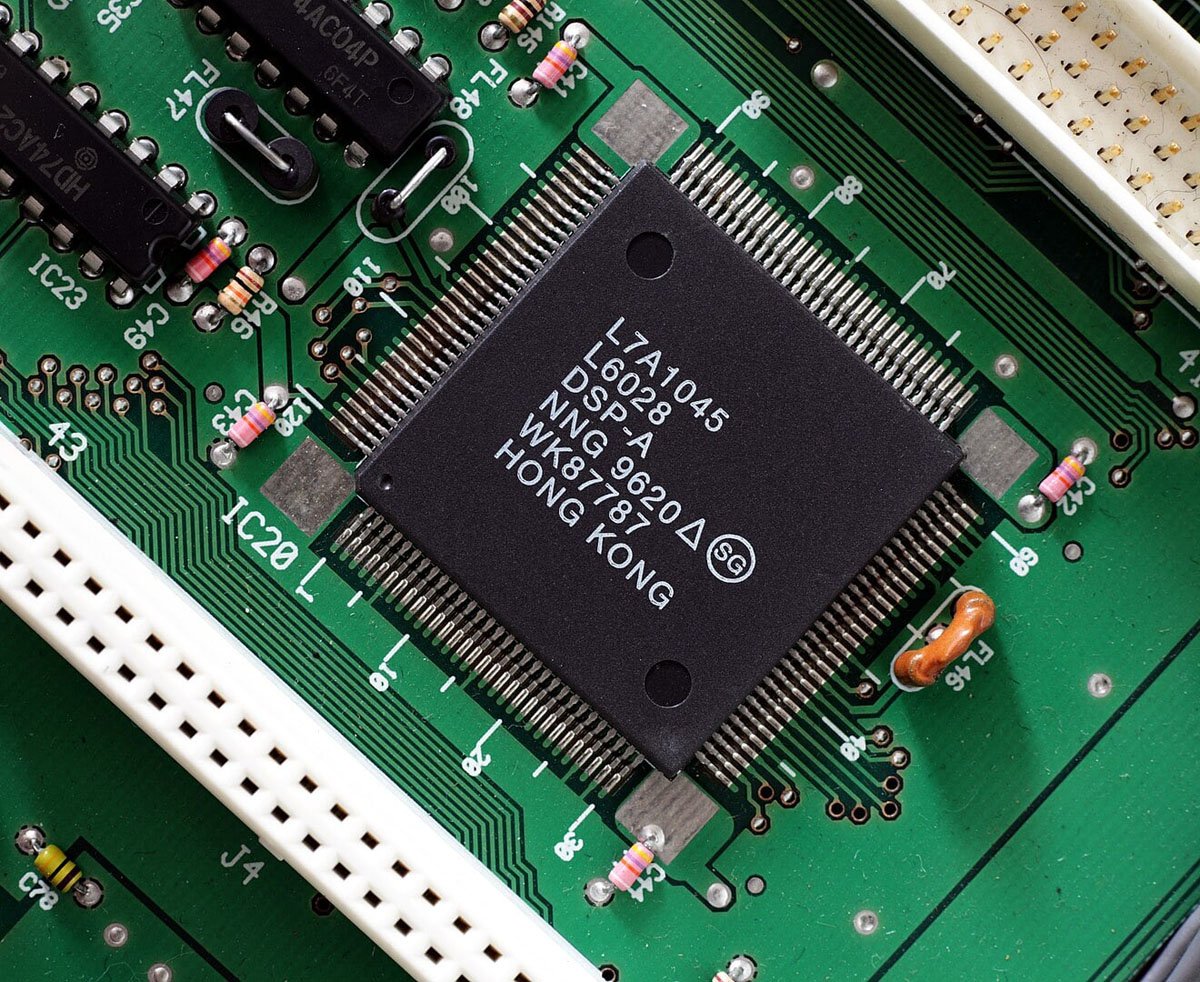

We move control from physical hardware to centralized software platforms.

- Zonal & Domain Control: Designing the high-performance computing (HPC) architecture, centralizing electronic control units (ECUs) into powerful, efficient domain or zonal controllers.

- Decoupling Hardware & Software: Implementing abstraction layers to separate application logic from hardware, enabling rapid iteration and future hardware upgrades without rewriting entire codebases.

- Middleware & Frameworks: Selecting and integrating the core software backbone (e.g., Adaptive AUTOSAR, ROS 2, customized middleware) to manage communication, security, and performance.

2. Feature Development & Lifecycle Management

The SDV unlocks new revenue streams long after the sale.

- Over-the-Air (OTA) Updates: Designing robust, secure pipelines for remote software deployment, enabling feature upgrades, performance tuning, and critical bug fixes.

- Function-as-a-Service (FaaS): Developing software features that can be activated on demand, enabling subscription models and personalized customer experiences.

- Functional Safety & Security (ISO 26262/ISO 21434): Integrating safety and cybersecurity protocols directly into the software architecture from the ground up, maintaining compliance throughout the lifecycle.

Software-Defined Engineering for Industrial Equipment

The same principles that define the modern vehicle apply to robotics, industrial machinery, and smart factory lines.

Agile Automation & Control

- Flexible Manufacturing: Implementing software-defined control logic that allows rapid reconfiguration of production lines through code updates, eliminating the need for extensive physical retooling.

- Digital Twins: Creating high-fidelity virtual models of your equipment, powered by the same code running on the physical system, for simulation, predictive maintenance, and fault detection.

- Predictive Maintenance: Using machine learning models deployed via firmware to continuously monitor machine health and schedule maintenance based on actual wear, not arbitrary timelines.

Why Choose Our SDE Expertise?

Traditional Approach | Our Software-Defined Approach | Result for You |

Fixed Functionality | Feature Agility & Customization | Generate New Revenue streams and adapt to market demands instantly. |

High Hardware Cost | Consolidated ECUs & Centralized Control | Reduced Complexity and a significant decrease in wiring, weight, and component cost. |

Long Development Cycles | Continuous Integration/Continuous Deployment (CI/CD) | Faster Time-to-Market for new features and superior quality control. |