The Future of Engineering Education: Why Every Lab Needs a Mechatronics Trainer Kit

Engineering is no longer confined to textbooks, lectures, or chalkboard diagrams. In a world shaped by automation, robotics, and Industry 4.0, tomorrow’s engineers need more than theoretical knowledge—they need hands-on experience with systems that mirror real-world challenges. This is where mechatronics trainer kits step in, making them an essential part of every modern engineering lab.

Why Traditional Labs Are Falling Short

Most engineering institutions still focus on isolated experiments—one lab for electrical, another for mechanical, and a separate one for programming. While important, this siloed approach doesn’t reflect how industries operate today.

Modern engineering demands:

- Integration of multiple disciplines (mechanical, electrical, electronics, and computer science).

- Problem-solving skills that require experimentation, not just memorization.

- Hands-on exposure to automation tools and real-time control systems.

Without bridging these gaps, students risk graduating with knowledge that feels outdated the moment they step into the workforce.

What Makes Mechatronics Trainer Kits Essential?

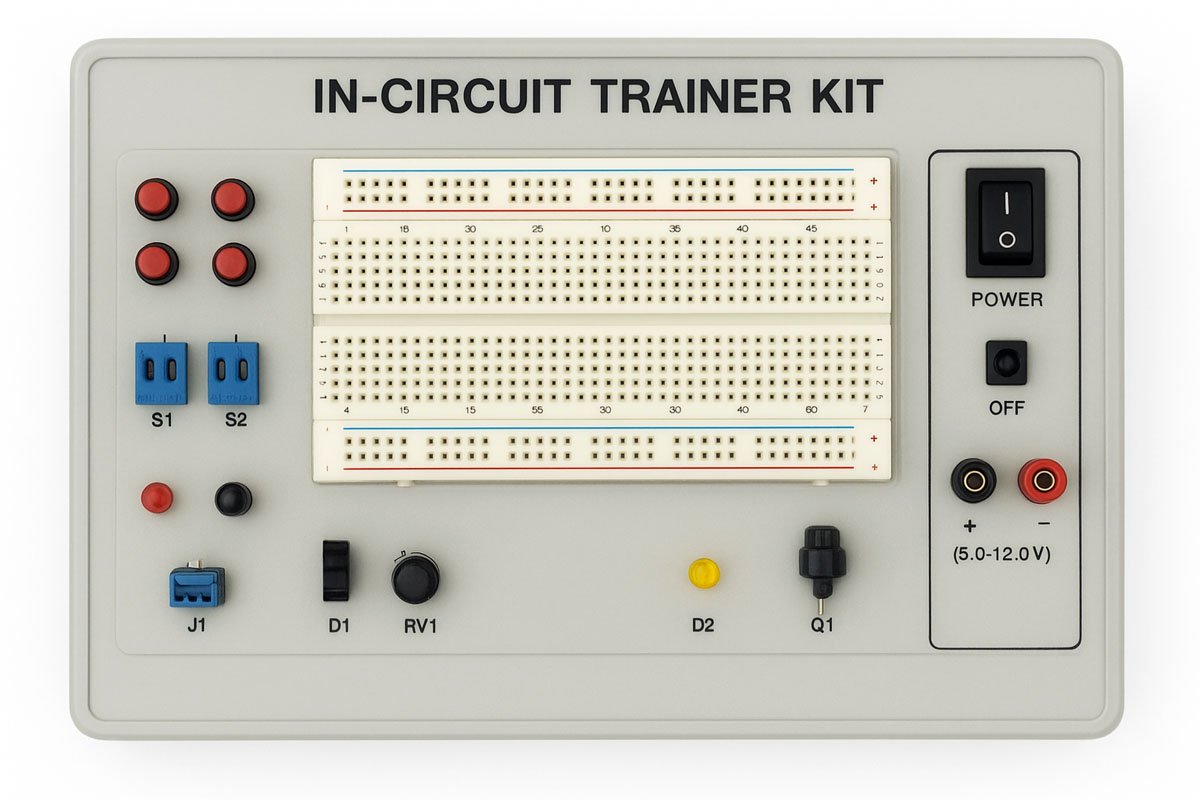

A mechatronics trainer kit combines mechanical, electrical, and control components into a compact, real-world training platform. It allows learners to design, test, troubleshoot, and optimize systems that reflect industry-standard automation and robotics processes.

In short, these kits bring theory and practice under one roof.

Benefits of Including Trainer Kits in Every Lab

1. Multi-Disciplinary Learning

Instead of treating engineering subjects separately, trainer kits encourage students to think about how systems interconnect and function together.

2. Industry-Relevant Training

From PLC programming to automation control, the kits simulate tasks engineers face in manufacturing, robotics, and smart factories.

3. Innovation & Creativity

Students can go beyond standard lab experiments, using kits to prototype, innovate, and test new ideas in a controlled environment.

4. Practical Problem-Solving

Failures in the lab turn into learning opportunities. Students learn debugging, system integration, and troubleshooting—skills that textbooks can’t teach.

5. Future-Ready Skills

Hands-on familiarity with sensors, actuators, and controllers prepares learners for careers in Industry 4.0, IoT, and smart automation systems.

Where Trainer Kits Add Value

- Universities & Colleges – Enhancing lab courses for mechanical, electrical, electronics, robotics, and automation streams.

- Polytechnics & Skill Institutes – Supporting hands-on, career-oriented training.

- Corporate Training Centers – Upskilling employees in automation and smart manufacturing.

- Research & Innovation Labs – Serving as prototyping tools for advanced projects.

Looking Ahead: Engineering Education 2.0

The future of engineering education is about collaboration, integration, and innovation. With industries adopting IoT-enabled automation, AI-driven robotics, and smart systems, labs must evolve to prepare students for tomorrow.

Mechatronics trainer kits are no longer optional—they are essential. They don’t just enhance learning; they future-proof education by ensuring students graduate with skills that matter in the real world.

Final Thoughts

Every engineering lab that invests in mechatronics trainer kits is investing in the future of its students and the industries they will lead. By bringing theory to life, these kits transform classrooms into hubs of creativity, innovation, and practical problem-solving.

In a competitive world, the difference between knowing and doing is everything—and mechatronics trainer kits make sure students can do both.